Service

When an event occurs and fast replacement is needed, Inossman North America is your reliable partner, the right choice. Contact us to check how we can support.

With multiple furnaces of different size, we are able to handle small lots and even single-item supplies.

Various 3D technologies are available to support our customer’s specific needs for each situation:

- 3D laser scanning so we can work even where no castings drawing is available by reverse engineering on existing parts. With an accuracy of 60 microns, create point clouds with our 458,400 points per second Opto Trak measurement system

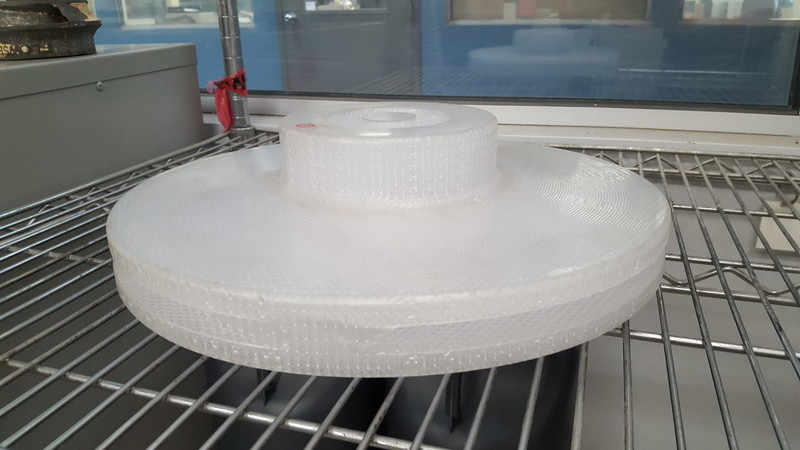

- 3D SLA printing for patternless production. Money and time can be saved to move faster to the castings’ production stage.

- 3D sand printing for precise molding and faster core set-up

We can support any delivery plan, even the fastest emergency supplies to the after-market.

Castings can be produced in a large span of Steel grades and Nickel alloys as required by the specific field of application: carbon steels, low alloys and high alloys, stainless steels (austenitic, martensitic, duplex and super duplex), heat resistant steels, up to nickel alloys.

.